Neologic Engineers makes no exception when it comes to providing innovative solutions for the processing lines.

Space is the concern for many food processing units and we offer them Spiral Solutions which are built using stacking technique.

Our water and energy-efficient Spiral Solutions help you speed up your process line with utmost precautions. To make things better, we have partnered with Fenco Food Machinery, Italy with which we are able to customize the state-of-the-art solutions for you.

Our Spiral Solutions are best suitable for the processing of

- Fruits & Vegetables

- Pasta & Pasta Sauces

- Pizza & Pizza Sauces

- Ketchup

- RTE/RTH/RTS

- Butter

- Ice cream

- Cheese

- Curd

- Meat

- Bakery Products

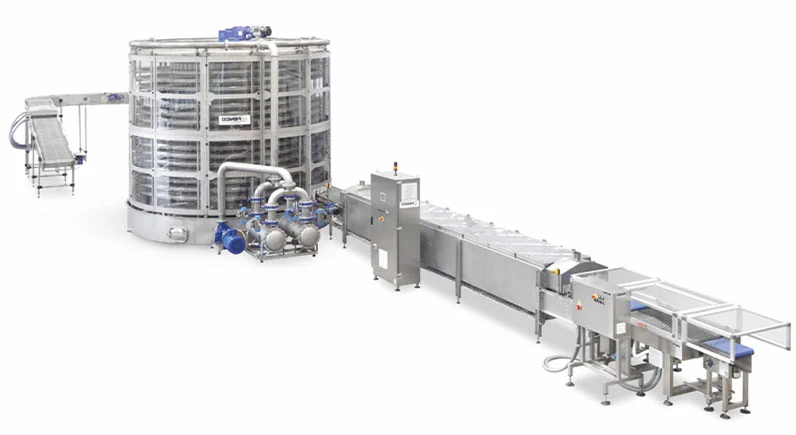

Spiral Water Cooler/Pasteuriser (SWC/SWP)

Our Spiral Water Coolers (SWCs) are space and energy-efficient. They occupy minimum space using stacking technique with minimum power requirement. They also utilize the minimum amount of water needed and water in the system is reused for maximum efficiency. The same goes for our Spiral Water Pasteurization (SWP) systems, which are used to eliminate pathogens in packaged foods. We use hot water, Cooling tower water & Chilled water, based on the product in case of both SWP and SWC. The water cooling and pasteurizing method is used for products such as packaged pasta sauces, Ready to Eat items etc.

- Collecting tanks underneath and recycle pump positioned at the lower part of the spiral

- Easy to open for washing, inspection and maintenance

- Flexible Stainless steel or Plastic belt for specific applications

- Spiral's structure made of stainless steel

- HMI PLC touch-screen with supervision system

- Very small footprint as compared to linear tunnel.

- Less power consumption in comparison with linear tunnel.

- Very compact design to minimize the space occupied.

- No need of any special flooring, neither concrete floors.

- The panels insulate perfectly both the Spiral Water Coolers and Pasteurizers.

- Accommodating multiple lines inside the same tower, independently or separately.

- No belt lubrication. All the mechanical parts and piping are external so no contamination.

- Very low water consumption.

- Collecting tanks underneath and recycle pump positioned at the lower part of the spiral

- Easy to open for washing, inspection and maintenance

- Flexible Stainless steel or Plastic belt for specific applications

- Spiral's structure made of stainless steel

- HDMI PLC touch-screen with supervision system

- Very less footprint as compared to linear tunnel.

- Very compact design to minimize the space occupied

- No need of any special flooring, neither concrete floors

- The panels insulate perfectly both the Spiral Water Coolers and Pasteurizers.

- Accommodating multiple lines inside the same tower, independently or separately.

- No belt lubrication, all the mechanical parts and piping's are out so no contamination

- Very low water consumption

Spiral Air Cooler/Pasteuriser (SAC/SAP)

Spiral Air Pasteurizers (SAP) and Spiral Air Coolers (SAC) are perfect for the processing of fruits and vegetables, pastas and pasta sauces, meats and bakery products. SAPs work without water and are perfect solutions for areas where water is not easily available or for products which are sensitive to water in the processing or packaging stage. Most importantly, more than one product can be treated using SAPs. This helps optimize maintenance and labour costs in the process without affecting the final quality of the product. We use atmospheric and chilled air to cool both packaged and non- packaged foods using SAPs and SACs.

- Higher thermal exchange on the product surface

- Improve thermal exchange and minimized time

- Quicker and faster thermal hot and cold penetration

- Final characteristics are maintained with minimum risk

- Completely water-freeconsumption

- Less maintenance costs

- Smaller footprint compared with traditional linear tunnels

- Accommodating different type of products packed products on same belt

- Final product standardization

- Production costs optimization

- No need to dry the product after cooling

- Higher thermal exchange on the product surface

- Improve thermal exchange and minimize the time

- Quicker and faster thermal hot and cold penetration

- Final characteristics are maintained with minimum risk

- Completely water-free consumption

- Less maintenance costs

- Saving of space compared with traditional linear tunnels

- Accommodating different type of products and/or packed products on same belt

- Final product standardization

- Production costs optimization

- No need to dry the product after cooling

Dryer

Pouch dryers are normally used to completely dry the wet pouches coming out from Retorts, Spiral water coolers & Spiral water pasteurizers. It ensures that depending upon requirement to maximum 0.05 gm of water is retained on pouch. This ensures that pouches move on line for cartoning without any stoppage.

This ensures high speed operation, maximum efficiency, and maximum effective utilization in existing machinery.

- High volume drying system

- SS 304 construction

- Suitable for cups, sachets and ready to eat pouches

- Modular construction to match capacities

- Consistent drying quality

- Speeding up the production line

- Elimination of manual labour

- Online packing option available

- High volume drying system

- SS 304 construction

- Suitable for cups, sachets and ready to eat pouches

- Modular construction to match capacities

- Consistent drying quality

- Speeding up the production line

- Elimination of manual labour

- Online packing option available

FENCO Food Machinery, Italy

for quality Spiral Solutions.

- Efficiency: Energy, cost and water-efficient spiral solutions

- Consistency: Spiral solutions made to deliver reliable and consistent performance

- Customization: Personalized spiral solutions as per your requirement

- Partnering the Competency: We believe in continuous improvisations in productivity and quality which has led us to our partnership with FENCO Food Machinery.

- No extra space: Stacking technique optimizes the available space so no extra space or special flooring needed.

- Low water consumption: Where SWCs &SWPs consume less water, SACs &SAPs work waterless.

- Easy wash: The structure of spiral solutions is designed to make it wash-friendly.

- Smaller footprint: Environment-friendly solutions leave smaller footprint reducing the ecosystem damage.

- Efficiency: Energy, cost and water-efficient spiral solutions

- Consistency: Spiral solutions made to deliver reliable and consistent performance

- Customization: Personalized spiral solutions as per your requirement

- Partnering the Competency: We believe in continuous improvisations in productivity and quality which has led us to our partnership with Fenco Food Machinery.

- No extra space: Stacking technique optimizes the available space so no extra space or special flooring needed.

- Low water consumption: Where SWCs &SWPs consume less water, SACs &SAPs work waterless.

- Easy wash: The structure of spiral solutions is designed to make it wash-friendly.

- Smaller footprint: Environment-friendly solutions leave smaller footprint reducing the ecosystem damage.

Our Clientele

Get in touch with our experts for your dairy equipment needs.

Our highly qualified team will help you right from concept to commissioning.

Frequent Searches: Spiral Solution