Automation Solution

for Food Processing Plants

- We provide the automation solution to the food & dairy processing industry. We also undertake revamping & modernization of the existing food processing plants to suitable automation level.

- Food automation companies like Neologic Engineers make automation in food processing industry easier. We aim at providing smart solutions to boost productivity regardless of the business’ size. Our techno-savvy and affordable solutions make achieving automation easy.

- Dedicated to every phase of production, we support you with front-of-line, processing, packing and handling, and end-of-line applications. With food processing automation, we aim at delivering better quality, improve picking and handling times and increase output by speeding up packaging processes. As a reliable food technology consultants, we believe that exceptional specialized automation results in lower costs and enormous competitive scope.

Aspects of Automation Engineering

- Function description is the heart of the process plant, which describes the various functions & automation level to the minute details. The core process knowledge is required to prepare this document.

- Design of the automation hardware like PLC, SCADA, HMI. According to required automation level, these components are selected. Remote IO,s configuration is most popular & comes to be economical.

- Designs of the panels, specifications of instruments, cable route, ear thing details, are required for each plant, which differ plant to plant.

- Design of application software is critical & important part of automation.

- This software is to be used for PLC & SCADA & which is designed as per the function description.

- MIS: The proper data logging is achieved & the same data is reproduced inform of reports, trends & charts as & whenever required.

- FAT (factory approval test) is done before plant start up to minimize the commissioning time & also to reduce the various risks.

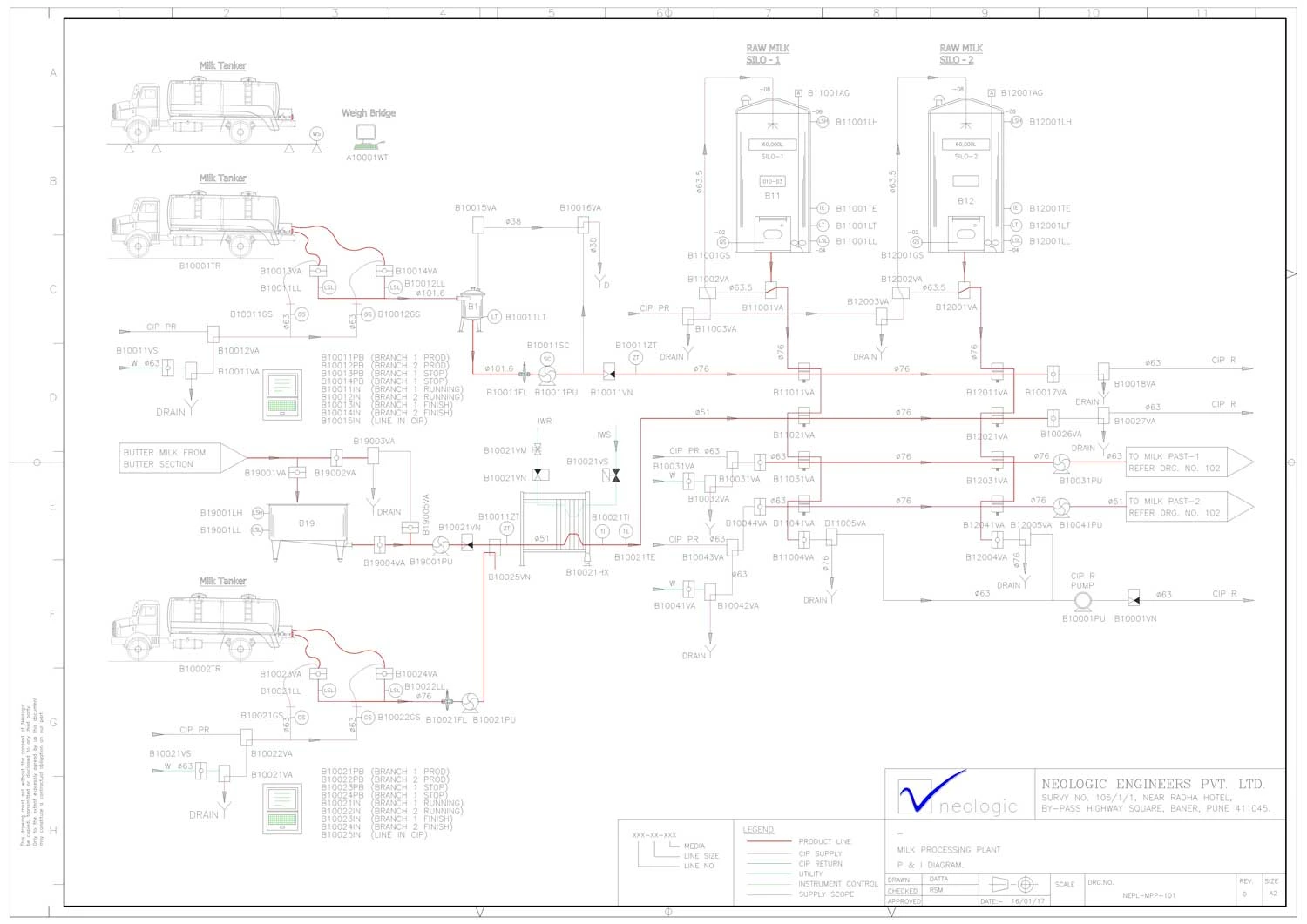

- We provide solutions from Milk reception unit to filling machine.

- Front-of-line automation: Front-of-line automation helps us to optimize your value chain. Right from depalletizing, loading, line charging to thermoforming packaging, a variety of tasks can be automated to help improve the food manufacturing processes and minimize costs.

- Automating delicate processes: From slicing, punching, cutting to filling, Neologic Engineers tailor-made solutions make it possible to automate almost every operation in food manufacturing. Our solutions are cost-effective and comply with food standard and hygiene regulations.

- End of line automation: Increases flexibility, provides intelligent and secure good-quality packing, storage and logistics. Wrapping, labeling, packing and palletizing can be done quickly and easily by automated systems.

- Automation Engineering: We provide automation solutions to the Food & Dairy Processing industry.

- Remote support 24/7.

- Operator safety package.

- Traceability.

- Tamper free solutions.

- Integration to business systems.

- As a food processing automation company, we help you prevent unplanned interruptions in your production.

- Work at an optimal level.

- Reduce operational cost.

- Improve environmental footprint and performance.

- Achieve better control of your operations.

- Energy Saving Solutions.

Frequent Searches: Food Processing Automation Company, Automation in Food Processing Industry, automation in food industry