Neologic Engineers Contherm Scraped Surface Heat Exchanger

Contherm Scraped Surface Heat Exchangers (SSHE) are at the heart of both continuous and semi-continuous viscous foods and personal care processes. The Contherm Core SSHE from Alfa Laval provides exceptional thermal efficiency, which is a prerequisite for viscous processing. Contherm Core ensures higher throughput, uniform heat transfer and more economical operation, compared to other heat exchangers. Contherm Core is designed to process low to medium viscous products.

Neologic Engineers’ skid-based manufacturing and cooking of viscous food products is equipped with the following equipment:

- Contherm pasteurizer with balance tank and set of valves

- Ribbon blender

- Paste unloading system

- Liquiverter

- Sugar syrup

- Ingredient handling

- Product recovery system/pigging process

Contherm Heat Exchanger Operations

All water-soluble ingredients are mixed and dissolved in water by using liquiverter. Sugar syrup prepared shall be stored in ready syrup storage tank. Tomato paste shall be unloaded from drums with special pneumatic or electric driven pumps. The paste is recovered by pigging system. All the ingredient are dumped in ribbon blender for mixing. Measured quantity of ingredients from liquiverter, sugar syrup, water, oil, paste etc. are dumped in ribbon blender.

The ribbon blender is specially designed to take care of gentle mixing of all in sequence. Properly mixed product then transferred to balance tank of Contherm pasteurizer for heat treatment. Scrapped surface heater, Contherm shall heat product to required temperature and shall be cooled to filling temperature. The product is directly filled to filling machines from pasteurizer.

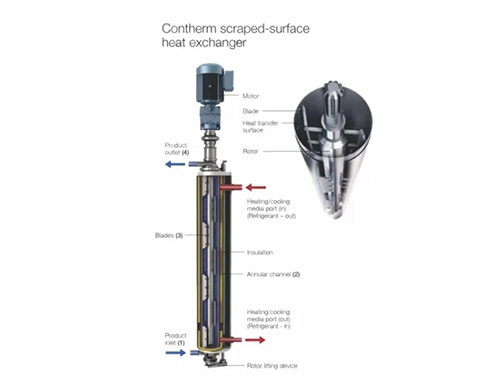

Working Principle of Contherm Scrapped Surface Heat Exchanger

Product is pumped into the Contherm heat exchange cylinder. As it flows through the cylinder, it is continuously mixed and removed from the cylinder's precisely finished wall by the scraping blades. This scraping action results in thin film product heating or cooling, a surface free from fouling deposits, and a corresponding high heat transfer rate. The drive can be adjusted for varied rotor speeds – an important feature when a number of different products are to be processed. Heating or cooling media flows in the annular space between the Contherm heat exchange cylinder and the insulated jacket.

When liquid media is used, a spiral coil is installed in the annulus to provide higher heat transfer efficiency. When utilizing steam, the coil within the Contherm Core annulus is removed. On start-up, air is completely purged from the Contherm. At the end of a processing run, the product can be drained or pushed by water, resulting in minimal product loss. The Contherm maximum flow rate is application specific and determined by the temperature program, nature of the product and type of duty.

Why Choose Neologic Engineers as your Contherm Skid Supplier?

Food, Dairy & Ice Cream category

- Sauces

- Ketchup

- Fruit purees & jams

- Baby food and desserts

- Khoa

- Chocolate and Ripple syrups

Personal care

- Skin lotions

- Facial cream

- Shampoo

- The 6x11 model offers 0.15 m2 (1.62 ft2.) larger surface area than other scraped-surface heat exchangers in the market.

- Features the same proven critical core components of the Contherm, including the heat transfer cylinder, seals, and blades.

- The Contherm Core can handle up to 25,000 cps and 25 mm (1 inch) particles.

- Optional flushed seals allow for aseptic processing.

- Optional high polished tangential heads (matte finish is standard).