Tomatoes are processed to prepare a variety of products such as peeled tomatoes, diced tomatoes, pastes, ketchups, sauces, juices, purees and more. We design and develop state-of-the-art Tomato Processing Lines.

Being the best fruit processing equipment manufacturer, we design advanced mango processing lines for a variety of products such as mango juice, mango pulp, candies, mango jam, marmalade and more.

We offer fruit processing equipment for processing of desiccated, sliced, shaved, grated coconut, coconut milk, coconut oil, coconut water, coconut defibring, coconut cream, coconut milk powder, candies, syrup etc.

We design and manufacture complete processing lines for tropical fruits such as papaya, sapota, guava, banana, mango, tomato, and other fruits to avail them in the form of juice, puree, pulp, jams, marmalade, paste etc.

Fruit and Vegetable Processing Machinery Manufacturers

As a responsible fruits and vegetable processing machinery manufacturer, Neologic Engineers believes that quality and hygiene parameters for fruits and vegetable processing equipment should be set from the beginning. Following the parameters, we have successfully served a considerable number of clients in every sector of fruits and vegetable processing.

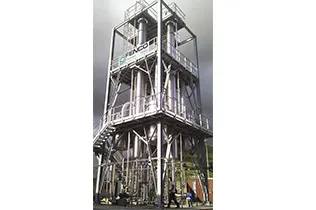

Our incomparable standards and efficient business solutions set us apart as a fruit processing equipment manufacturer. We have exclusive partnership with FENCO and they have branded Neologic Engineers as one of their best vegetable processing equipment manufacturers.

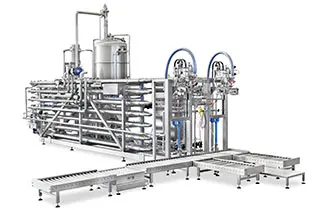

We have set our goals to deliver the top-quality products. Our juice manufacturing plant includes preparatory material, turbo refiner, pre-heaters, pasteurizer, evaporators, aseptic sterilizers etc. which serve as ideal plant for tropical fruit and vegetable processing.

Productivity, Quality & Cost-effectiveness

We value productivity, quality and cost-effectiveness of our fruit and vegetable processing equipment. Our hi-tech processing machineries deliver the high operation value and help you produce the best quality final product. In terms of tomato or mango processing equipment, our optimized processes and specialized machines help in obtaining fine quality paste, sauce, purees and juice.

Our dedicated expert team ensures the high efficiency and ideal performance of our entire fruit and vegetable processing equipment range. We focus on making our equipment time-saving for quicker fruit and vegetable processing. We also apply that time-efficiency into our manufacturing processes to deliver your processing equipment at the earliest.

We are recognized as a reliable fruit and vegetable processing machinery manufacturer. Apart from our manufacturing and supply chain solutions, we also offer:

- Washing and sorting of the fruits with the help of the water filtering system.

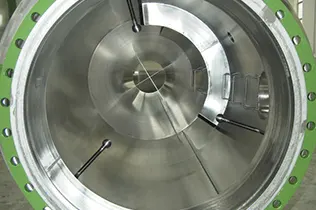

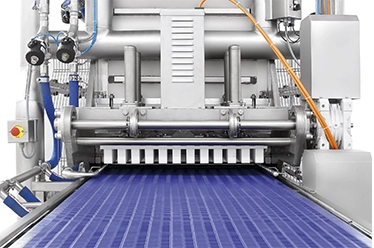

- Juice extraction with the help of a hot break technology equipment that is available in latest designs.

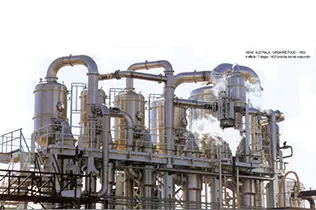

- Circulation of fruits with the help of evaporators and vapor recompression

- Aseptic tank manufacturing & filling line which helps in treating viscous products

Here are some of the qualities that make us stand apart among our competitors:

- Our fruit juice products go through stringent quality checks.

- Along with the juice processing machines and the final packaging, we make sure that every step is carried out with completeefficiency.

- Best products offered at competitive prices.

- Our juice processing equipment is made from stainless steel and can be operated at different temperatures.

- No compromise laid on the use of machinery and latest techniques in the production process.

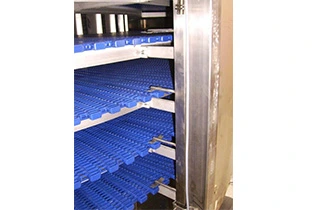

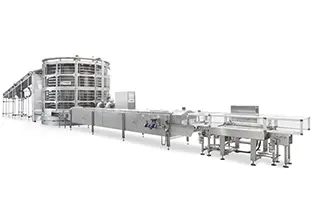

- You can avail our unique range of freezing solutions, spiral solutions, dryers and coolers for unparalleled food processing equipment results.

Our Clients

At Neologic, utmost importance is given to quality and supremacy. With precise customized solutions.

Business Segments

Frequent Searches: Fruit and Vegetable Processing Machinery Manufacturers, Vegetable Processing Equipment Manufacturers, Fruit Processing Equipment Manufacturers