Leading Dairy Processing Equipment Manufacturer

Neologic Engineers was founded in 2007, and since then, we have strived to be one of the best dairy plant machinery manufacturers with our Turnkey project solutions, covering the following areas:

- Liquid Milk Processing, Standardization, Homogenization & Storage

- Pasteurized Milk Fat/SNF Standardization & Cream Processing

- Complete Dairy Automation

- Curd, Lassi & Butter Milk Processing & Packing Lines

- Yoghurt (Stirred & Set), Greek Yoghurt Processing Plants

- UHT Aseptic Dairy Processing with Aseptic Storage

- White Butter and Ghee Manufacturing Plants

- Ice Cream Mix Processing Plants

- Paneer Processing Lines

- Cheese Processing Lines

- Modernization of Processes and Plants

- Cleaning in Place (CIP Systems)

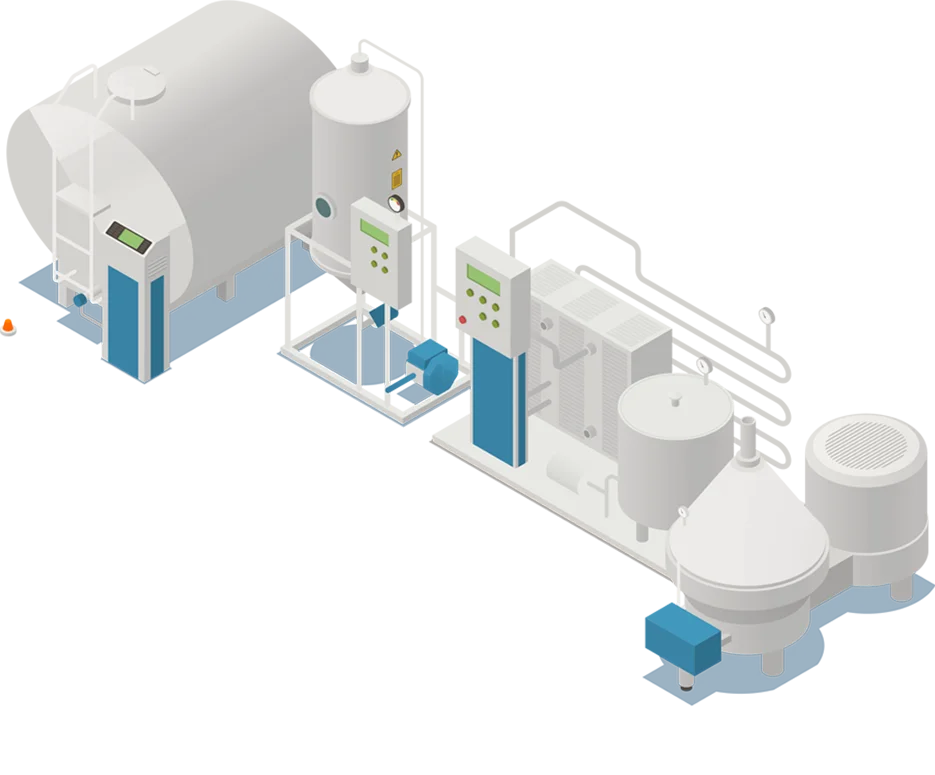

Liquid Milk Processing, Standardization, Homogenization & Storage

Processing applications for dairy milk and dairy by-products.

We design, engineer, and supply complete plants, processing lines, and equipment for treating raw milk and also for manufacturing, filling, and packaging pasteurized pouch milk, UHT milk packed in aseptic packaging, and milk-based products of – Curd, Lassi, Yoghurt (all types), Misti Dohi, Butter Milk, Flavored Milk, Milk Beverages, Ice Cream Mix Processing, Paneer and cheese.

Our range of processing systems and complete process lines have been developed to ensure that every stage of milk processing, from milk reception and clarification, heat-based pasteurization and homogenization, to final product processing and storage, meets the most stringent safety requirements without losing valuable nutrients in the milk.

Pasteurized Milk Fat/SNF

Standardization & Cream Processing

Neologic Engineers is the most preferred Dairy Processing Equipment Manufacturer that offers solutions for the production of milk fat products including butter and ghee. The design of our equipment and plants is backed by expertise in every stage of milk fat processing, from Raw Milk Reception to Buffer Tanks, Pasteurization, Homogenization, Ripening Tanks, Butter Churning, Butter Melting, Heating, Cooling, Storage, and Filling. Whether the final product is ready-to-eat, ready-to-cook, or used as an ingredient in the food industry, our processing line solution ensures that it will exhibit the best possible quality, taste, and texture.

Complete Dairy Automation

Full plant integration starting from Milk Reception up to the final Product Packing ensuring maximum efficiency at all stages, product safety, and minimum wastage. Our Dairy Automation Solutions are built to capture process data to monitor performance and product quality in real-time. We generate reports that enable preventive maintenance to keep the system running reliably and consistently. By giving you access to all the pertinent real-time operational data, as a responsible Dairy Processing Equipment Manufacturer, we can help you gain a better understanding of what is happening in your plant, which will lead to improved plant performance.

Curd, Lassi & Butter Milk Processing & Packing Lines

Neologic Engineers can offer complete lines for these Fermented milk by-products. We are a Dairy Equipment Manufacturer that manufacture lines for batch or continuous processing, depending on the capacity. Our solutions can ensure the right product quality and meet the local industry norms.

Yoghurt (Stirred & Set), Greek Yoghurt Processing Plants

We understand your end product requirements and can offer you a customized line solution for these niche Fermented milk by-products. These lines can be batch or continuous processing, depending on the capacity. Our solutions can ensure the right product quality and meet the local industry norms.

UHT Aseptic Dairy Processing with Aseptic Storage

We are the leading Indian Dairy Processing Equipment Manufacturer of complete UHT Aseptic Lines for Continuous Sterilization, Aseptic Buffer Storage, and Aseptic Packaging of Milk and Milk By-products like Flavored Milk, Drinking Yoghurt, Cream, etc.

White Butter and Ghee Manufacturing Plants

If you’re setting up a Milk Powder Plant, then we are Dairy plant equipment & line Manufacturer who can supply the complete Processing sections for Milk, Cream, Butter, and Ghee. With options in White Butter Making that can be investment friendly, we can offer the complete Ghee Line made from White Butter. Our Ghee Processing and Packing lines are known for their high yield and low losses through the blend of innovative and practical processing ideas.

Ice Cream Mix Processing Plants

Whether you are making conventional Ice Cream products, Frozen Desserts, Ice Candy (Water Ice), the traditional Kulfi, or Natural Ice cream, being amongst the most responsible Dairy Equipment Manufacturers, we understand your product needs first and then offer our Mix Processing lines that will be fully customized. These line solutions would also be optimized to balance the need for process Automation and Investment required.

Paneer Processing Lines

Our Paneer processing equipment has been tried and tested based on quality standards demanded by the industry and product quality requirements. Along with the customized equipment for each plant, we make sure that the equipment for each process step delivers high efficiency and same time deliver value for money at competitive prices. Apart from that, we are a Dairy Equipment Manufacturer that always uses branded equipment of superior specifications, high quality & reliability that will help in ensuring the correct manufacturing process for high-quality Paneer production of the right texture that meets industry standards at every single level.

Cheese Processing Lines

Our medium & small capacity Mozzarella cheese processing equipment range comprises a completeproduction line from fully enclosed Cheese Vats, Whey Draining Equipment, Cooker Stretcher, and Molding Solution for various sizes, followed by the Brining and Cooling equipment. For the key Cheese Equipment, Neologic Engineers has a tie-up with a reputed Cheese Equipment manufacturer from Italy.

For medium and small capacity Natural Cheese Lines with economic investment, we are a Dairy Equipment Supplier to provide complete lines for Cheddar cheese, starting from Closed / Open Cheese Vats, Cheddaring, Salting, Finishing Vats & right up to the Cheese Press of our proven design.

The cheese processing equipment is made from total hygienic grade stainless steel materials and hygienic, cleanable designs that operate at a preferred temperature and deliver final products that are both superior in quality and taste. Along with the Cheese Milk Processing, we provide a wide range of dairy equipment in the processing line.

Modernization of Processes and Plants

Technologies, equipment, and systems are constantly developing to deliver higher and better outputs at lower operating costs. We keep abreast of the developments in the industry and thereby ensure you get the latest solutions in our new plants. We also audit existing plants to explore areas of plant improvement and bring in modernization, wherever possible.

Cleaning in Place (CIP Systems)

Our CIP cleaning system is designed to control the key cleaning parameters with higher accuracy. As per the standards to be followed by the Dairy Equipment Supplier, we include the parameters of temperature, flow, and concentration of detergent and water, combined with the time the detergent needs to be in contact with soiled equipment to clean it. This makes the cleaning of equipment economical in terms of time spent (thereby increasing production uptime) and minimizing the utilities consumed. It also prevents potential food safety risks. CIP takes place either after a processing run – what we call 'normal fouling' - or when switching production from one recipe to another.

Authentic Turnkey Project Solutions by Dependable Dairy Processing Equipment & Line Manufacturer

Neologic Engineers has established its name as the most reputed Dairy processing line manufacturer since 2007. Along with best-in-class milk processing equipment and lines with various other modern manufacturing units ensure up to the mark dairy processing. Our dairy processing equipment is designed for the preparation, processing, and slicing of a variety of cheeses, ice cream mix processing and products, milk by-products, and much more. Our highly efficient and easy-to-use operational production lines produce the best quality products.

With the full-fledged range of equipment, we aim to accomplish the best performance. As a globally preferred Dairy Plant Machinery Manufacturer, our prime focus is on improving the productivity, quality, and cost-effectiveness of dairy products. Our team of experts provides reliable and robust solutions to create positive and measurable results.

- We undertake complete design, engineering, project management, supply, erection, and commissioning of dairy plant equipment and their utilities for turnkey projects and dairy greenfield projects

- Complete care of dairy automation and its up-gradation by expert Dairy Equipment Manufacturer

- Undertake project engineering consultancy, project process design, process economy and feasibility, utility design, and supply

- Wehave a professional, experienced & skilled team of Engineers & Technologists

- Established production lines at many dairies with long-term satisfactory operation.

- Cost-effective solutions, in terms of both CAPEX and OPEX

- The Dairy Plant Equipment Manufacturer with efficiently functioning Dairy Processing Systems and Equipment

- We have repeat orders from our customers demonstrating their satisfaction in our delivered projects

Business Segments

Frequent Searches: Dairy Equipment Manufacturers, Dairy Plant Machinery Manufacturers, Dairy Processing Equipment Manufacturers, Dairy Processing Solutions