Ultimate Ice Cream Processing Guide: All You Need to Know

Ice cream manufacturing is a complex process that requires precision, efficiency, and adherence to stringent hygiene and quality standards. As consumer demand for premium and innovative ice cream flavors grows, manufacturers must optimize their production processes to maintain consistency, taste, and shelf life. This guide provides a comprehensive overview of industrial ice cream processing, from ingredient selection to final packaging.

Ice Cream and Its Composition

Industrial ice cream refers to large-scale, commercially produced ice cream designed for mass distribution. Unlike artisanal or homemade ice cream, industrial ice cream is manufactured using automated processes in highly controlled environments, ensuring consistency in taste, texture, and quality. It is widely available in various forms, including bulk packaging for food service, single-serve cups, family-sized tubs, novelty bars, and soft-serve mixes.

The Indian ice cream market has been experiencing significant growth, driven by factors such as rising disposable incomes, urbanization, and evolving consumer preferences. In 2023, the market was valued at approximately USD 3.46 billion. Projections indicate a compound annual growth rate (CAGR) of 15% from 2025 to 2034, with the market expected to reach around USD 12.17 billion by 2034.

Ice Cream – Mix Types Composition

| Ice Cream | Water Ice | Kulfi | |

|---|---|---|---|

| Dairy Fat at % | 10 | 0 | 15-20 |

| MSNF % | 11 | 0 | 25-30 |

| Sugar % | 14 | 22 | 15 |

| Liquid Glu | 0-5 | 0 | - |

| E/S % | 0.4 | 0.2 | - |

| TS % | 36 | 25 | 60-70 |

| Overrun % | 100 | 0 | 0 |

| Veg Fat | Only in FD |

Key Stages in Ice Cream Processing

The foundation of high-quality ice cream lies in the careful selection of ingredients, including:

1. Ingredient Preparation

- Milk and Cream: The primary dairy ingredients that contribute to the texture and mouthfeel.

- Sweeteners: Sugar, Liquid Glucose, corn syrup, or artificial sweeteners to enhance taste.

- Stabilizers and Emulsifiers: Essential for maintaining consistency and preventing ice crystallization.

- Flavorings and Additives: Vanilla, chocolate, fruit extracts, and mix-ins like nuts and candy pieces.

2. Mixing and Homogenization

Once the ingredients are measured and blended, the mixture undergoes homogenization to break down fat globules and ensure uniform texture. This step enhances the stability of the final product and prevents fat separation.

3. Pasteurization

To eliminate harmful bacteria and extend shelf life, the mix is heated to specific temperatures based on regulatory requirements. Common pasteurization methods include: High-Temperature Short Time (HTST): Heating to 72°C for 15 seconds.

4. Aging

After pasteurization, the mix is cooled to around 4°C and aged for 4-24 hours. This step improves emulsification, allowing fat globules to crystallize and enhance texture.

5. Freezing and Air Incorporation

The aged mix is fed into a continuous or batch freezer, where it is rapidly cooled while incorporating air (overrun). The level of overrun influences the density and mouthfeel of the ice cream.

6. Inclusion of Mix-ins

At this stage, ingredients like chocolate chips, fruit pieces, or cookie dough are added using a controlled dosing system to ensure even distribution.

7. Hardening and Storage

The semi-frozen ice cream is transferred to packaging units and hardened at -30°C or lower in blast freezers to lock in texture and prevent ice crystal formation. Once hardened, the product is stored at -18°C or below until distribution.

Advanced Ice Cream Processing Equipment

1. Mix Pasteurization and Homogenization

Total TS can range from 37% to 45%. The use of certain stabilizer blends can significantly increase mix viscosity, reaching up to 2000 cPs. High-viscosity mixes, combined with an improper PHE model or design, can lead to several challenges, including:

- Reduced run time and PHE choking

- Drop in pasteurization temperature

- Lower regeneration efficiency and increased steam consumption

- Solids buildup and fouling over time

- Ineffective CIP

Implementing two-stage homogenization with the appropriate homogenization head helps mitigate these issues, ensuring smooth operation and process efficiency.

2. Freezers

- Batch Freezers: Ideal for artisan-style production.

- Continuous Freezers: Suitable for large-scale industrial manufacturing, allowing controlled air incorporation.

3. Ingredient Dosing Systems

Automated ingredient dosing ensures accurate mix-in distribution, preventing inconsistencies in the final product.

4. CIP (Clean-in-Place) Systems

Hygiene is critical in dairy processing. Automated CIP systems help manufacturers maintain stringent sanitation standards, reducing downtime and ensuring compliance with food safety regulations.

5. Flavor Mixing, Pumping to Freezers

The number of IC production lines and freezers determines the allocation of flavor mixing tanks (FMTs). FMTs are connected to freezers locally through flow plates, with dedicated groupings linking FMTs to freezers and production lines. However, production operations require flexibility in connecting FMTs to freezers across different groups.

A centralized CIP system ensures thorough cleaning of FMTs, mix lines up to the freezers, and all flow plate ports. Additionally, continuous freezers undergo central CIP, with route selection feedback integrated into the central system. Automation enables real-time monitoring and CIP reporting, ensuring a high level of plant hygiene.

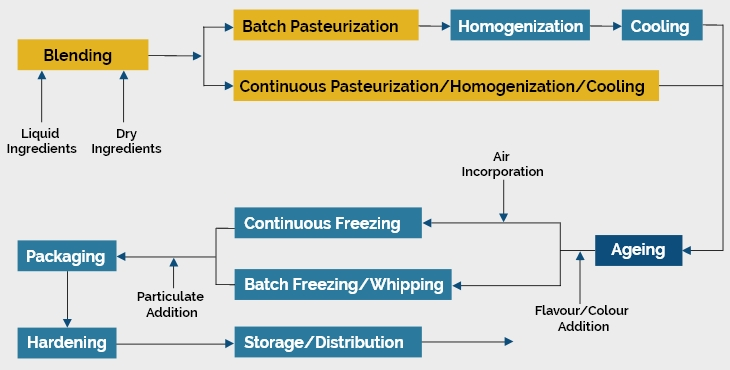

Ice cream processing process diagram

Ensuring Quality and Compliance

Manufacturers must adhere to Good Manufacturing Practices (GMP), HACCP guidelines, and FSSAI/BIS standards in India to ensure product safety. Neologic Engineers provides cutting-edge automation and process control solutions to help manufacturers meet stringent regulatory requirements.

Ice cream processing is an intricate balance of science, technology, and quality control. From precise ingredient mixing to advanced freezing techniques, every step contributes to the final product's taste and texture. By investing in state-of-the-art processing equipment and automation, manufacturers can enhance efficiency, maintain consistency, and meet evolving consumer demands.

Webinar: Optimized System Solutions for Ice Cream Mix Processing Plants

Get a deeper understanding of having the right and optimum process equipment for your ice cream mix preparation in our Emerging Food Tech Webinar series.