Know Everything About the Food Processing Industry

The Food Processing Industry is the Sunrise Sector of India, one of the largest in the world. It is expected that by 2025 the Indian Food Processing Market will grow at an annual growth rate of 15.2%. So, let’s dive deep into the Food Processing Industry and learn about the food processing industry in India.

What is Food Processing?

Food processing and preservation have been a part of humanity since prehistoric times. Food processing converts agricultural produce like grains, millet, vegetables, etc., into food ingredients or processed food. Sun drying, preserving with salt, fermenting, and cooking using different methods like roasting, smoking, steaming, and oven baking are ways of processing food.

Different Levels of Food Processing

Food processing plays an important role in reducing the amount of food waste. Processed food also has a longer shelf life and is better for long-distance transportation. The different levels involved in processing and fermentation in food processing are:

- Primary: The primary level processing converts agricultural produce into food items that can be consumed in the future. It increases the shelf life of the farm products. To lower the risk of injury, this level also has control systems including failure mode and effects analysis (FMEA), hazard analysis and critical control points (HACCP).

- Secondary: The secondary level of food processing involves altering a basic food product into a processed food product. One conventional method of secondary food processing is the fermentation of food items.

- Tertiary: The commercial manufacturing of what is popularly referred to as processed food is known as tertiary food processing. These items are ready-to-eat, ready-to-heat and ready-to-serve, like frozen and warmed-up meals.

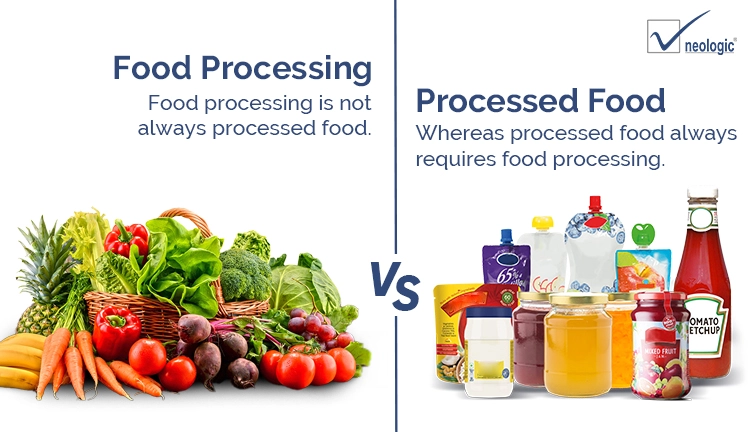

Food Processing Vs Processed Food

Food processing is defined as the method that involves the use of equipment that transforms agricultural products into food ingredients or finished food products. For example: rice, grains, fruits, meat, vegetables, etc.

Processed food on the other hand is a form of food processing where the form of a food item is converted by adding external elements. Processed food is a combination of food ingredients that are mixed together resulting in shelf-stable food, convenient to reheat or cook in the oven, and palatable. For example: cheese dips, ready-to-eat cereals, potato chips, salad mixes, etc.

Processed food requires food processing, but not all food processing gets converted into processed food.

Methods of Food Processing

Food processing involves various methods to transform raw ingredients into food products that are safe, palatable, and suitable for consumption. While processing food you need to consider the possibility of pests or bacteria that could multiply in the food item. To prevent this, various food preservation measures are required to be taken.

Several food preservation methods designed to preserve food are:

- Thermal processing includes pasteurization, sterilization, and blanching. Pasteurization involves heating food to a specific temperature for a set period to kill harmful microorganisms, commonly used for milk and fruit juices. Sterilization, which is more intense than pasteurization, is often used for canned foods to ensure all microorganisms are destroyed. Blanching, typically used for vegetables before freezing, involves briefly boiling food to inactivate enzymes.

- Freezing and refrigeration are crucial methods for preserving food. Freezing rapidly lowers the temperature of food to preserve it by slowing down enzymatic and microbial activity, suitable for fruits and vegetables. Refrigeration keeps food at low temperatures (usually between 0-4°C) to extend the shelf life of dairy products, fresh produce, and ready-to-eat foods.

- Dehydration and drying methods, such as air drying, freeze-drying, and spray drying, remove moisture from food to preserve it. Air drying is used for fruits, vegetables, and herbs, while freeze-drying, involves freezing food and then reducing pressure to allow ice to sublimate. Spray drying converts liquid food into dry powder by rapidly drying with hot gas, generally used for milk powder.

- Fermentation processes, both traditional and controlled, use microorganisms to convert sugars into organic acids. Traditional fermentation is used for yoghurt, enhancing flavour and nutritional value. Controlled fermentation is used on an industrial scale for consistent quality in products like probiotics and soy sauce.

- Irradiation, including gamma irradiation, exposes food to radiation to kill bacteria and pests, extending shelf life.

- Extrusion cooking forces food material through a shaped hole in a die using high temperature and pressure, cooking and shaping the food simultaneously. This method is used for breakfast cereals, pasta, pet foods, and snack foods.

- Canning involves sealing food in containers and heating to destroy microorganisms. Aseptic canning sterilizes food and packaging separately and then combines them in a sterile environment, used for fruit juices and soups. Traditional canning seals food in cans or jars and heats them, suitable for vegetables, fruits, and ready-to-eat meals.

- Chemical preservation includes adding preservatives and pH control. Adding chemicals like salt, sugar, and acids inhibits microbial growth, used for pickles and jams. pH control adjusts the acidity of food to create an environment unsuitable for microbial growth, preserving food like pickled vegetables.

- High-pressure processing (HPP) or cold pasteurization subjects food to high pressure to inactivate bacteria without using heat, preserving the taste and nutritional quality, used for juices.

- Enzymatic processing involves adding specific enzymes to food to modify properties, such as clarifying fruit juices. This enhances the texture, flavour, and appearance of food products.

- Emulsification is essential for creating stable food mixtures. Emulsification mixes two immiscible liquids to create a stable emulsion, used in mayonnaise and salad dressings.

- Homogenization breaks down fat molecules in liquids to create a uniform mixture, used in milk and dairy products to prevent separation and improve texture.

Food preservation is a method to prevent the growth of any fungi, bacteria, pests, etc., in the food processing process. It slows down the oxidation of fats which would lead to rancidity in the product.

Which Food Processing Equipment is Used?

The food processing industry in India has a huge market base and various levels on which the food is processed. Different levels of processing come in with high standards of processing requirements that need to be maintained by every food processor.

The food processing equipment has a wide range of machinery designed to handle various stages and types of food production varying from low viscous to high viscous products. These machines ensure efficiency, consistency, and safety in transforming raw ingredients into finished products.

Here are the different types of food processing equipment:

- Pasteurization System: Pasteurization is a heat treatment process that destroys pathogenic microorganisms and reduces the total bacterial count in the products. The process involves heating the product to a specific temperature for a set period and then rapidly cooling it.

It prolongs the product's shelf life and has a regeneration efficiency of up to 93%. A pasteurization system is used in milk, cream, ice cream mix, curd milk, yoghurt, and juice processing. Pasteurization can be done in two ways:

- HTST (High-Temperature Short Time): Heating to 72°C (161°F) and holding for 15 seconds.

- LTLT (Low-Temperature Long Time): Heating to 63°C (145°F) and holding for 30 minutes.

- CIP System: An automated Clean-in-place (CIP) System mechanically cleans the processing lines to remove residues from the whole process plant, fittings, tanks, and piping circuits. It maintains hygiene and prevents contamination without disassembling the equipment. Installing a CIP system improves the equipment performance and enhances product quality. It is cost-efficient, reduces water consumption and is environment friendly.

- Aseptic Storage Tank System: The aseptic storage tank is the intermediate equipment between the aseptic sterilizer and filling machines. Aseptic storage tanks store sterilized products in a sterile environment to prevent contamination until packaging. The aseptic valve cluster in the module maintains sterility. It encloses sanitary valves with a steam barrier, a sterile air system with micron filters, instrumentation, a control panel, a control system and a touch screen HMI.

- UHT Sterilization Module: UHT (Ultra-High Temperature) sterilization involves heating products to extremely high temperatures for a very short time to achieve commercial sterility. UHT heating goes up to 135°C (275°F) for 2-5 seconds. This module is used for products that require a long shelf life i.e. up to one to two years. UHT Sterilizers can be used by direct (steam injection or infusion) or indirect heating (heat exchangers).

- Spiral Solutions: Spiral solutions in food processing typically refer to spiral freezers and conveyors. Some processed foods such as food in pouches, cups, and sachets that require cooling after packaging can be cooled using Spiral Water Coolers (SWC). Spiral Water Coolers are space and energy-efficient. A Spiral Water Pasteurization System (SWP) is used to eliminate any pathogens in packaged foods.

Food Processing Systems Used by Neologic Engineers

The product lines supplied by us comprise of an advanced Automation system along with complete processing lines. Our food processing system comprises of:

- an automated system,

- a vacuum cooking system,

- a pressure-cooking system, and

- processing lines for ready-to-eat food items.

Our equipment includes Heat Exchangers, Packaging Machines, and other Food Processing Machines.

The different types of food processing systems provided by Neologic Engineers:

- Ready-to-Eat (RTE), Ready-to-Heat (RTH), and Ready-to-Serve (RTS): This line consists of a blending preparation system for sugar, sauce, grave, and sauté. This line also comes in with grain handling, buggi handling, vertical loading system and cooking system in cooking kettles.

- Tomato Ketchup Preparation: This line consists of an aseptic tomato paste unloading system, raw sugar unloading and transfer system, sugar syrup preparation and storage system, and starch/xanthan gum/pectin/spice preparation system. This line also consists of systems for blending, DSI and deaeration, homogenization, hot fill and cooling.

- Sauces and Gravies Preparation: This line consists of systems for raw tomato handling with slicer and dicer, onion peeling handling, ginger and garlic peeling and grinding, pulverizer, buggi lifting and a multipurpose kettle. It also comes with a Sauté Preparation System.

- Jams and Marmalade

- Mayonnaise Preparation: This line consists of systems for oil unloading and storage, vinegar unloading, stabilizer/salt/sugar preparation, ingredients mixing and pigging.

The food processing system supplied by us undergoes a stringent quality check and the food processing equipment used by us is made from high-quality materials. Right from food processing machines to the supply process, every step is carried out with complete efficiency and its functional features can be used for customization as well.

Food Industry in India

The food processing industry is one of the major contributors to the Indian economy. The Ministry of Food Processing Industries (MoFPI) has implemented various schemes and initiatives to support this industry; Pradhan Mantri Kisan Sampada Yojana (PMKSY), Pradhan Mantri Formalization of Micro Food Processing Enterprises (PMFME), and Scheme Production Linked Incentive Scheme for Food Processing (PLISFPI). The main objective of these initiatives is to promote investments to stimulate growth and offer financial, technical, and business aids to establish food processing enterprises.

The market size of the food processing industry in India is expected to reach US$ 1,274 billion by 2027 and the food consumption is expected to reach US$ 1.2 trillion by 2025-26. The government approved 100% Foreign Direct Investment (FDI) under the automatic route to make the FDI policy more investor-friendly, and the food processing units are qualified for complete profit exemption in the initial five years.

For setting up and operating cold chains or storage warehouses for agricultural produce, Income Tax deductions at the rate of 150% are allowed. In the fiscal year 2022-23, India exported USD 1635.95 Million (Rs. 13185.30 crores) worth of fresh fruits and vegetables (as per APEDA report).

The infrastructure for food processing is rising at a brisk pace after the launch of the Mega Food Parks Scheme by the Ministry of Food Processing Industries. To date 24 out of 42 mega food parks are established and are fully functioning. Along with the Mega Food Park Scheme, MoFPI also introduced a scheme for Cold Chain Processing units, and to date 8.4 lakh metric tonnes of cold storage capacity has been created.

Food Safety and Quality Management in Food Processing Industry

The food processing industry, given its scale, can inadvertently become a source of significant foodborne illnesses. The pressure to maintain profitability often leads to cutting corners and neglecting essential details. While regulatory agencies such as the U.S. Department of Agriculture (USDA) and the Food and Drug Administration (FDA) oversee food safety, the onus remains on individual food manufacturers to implement and diligently follow food safety protocols.

Importance of Food Safety and Quality Management

- Consumer Health Threats: Ensuring compliance with food safety standards is paramount, as non-compliance can adversely affect consumer health, leading to severe consequences from adulterated practices.

- Business Risks: Any malpractice or the growth of harmful bacteria within products or production lines poses a constant threat to business operations, potentially leading to costly recalls and damage to reputation.

- Legislation and Standards: Adherence to various legislative frameworks and standards is crucial. These include ISO 22000:2018, the Food Safety and Standards Authority of India (FSSAI), the Central Drugs Standard Control Organization (CDSCO), the Essential Commodities Act, the Standards of Weights and Measures, Industrial Licenses, and voluntary standards from the Bureau of Indian Standards (BIS).

- Food Inspection Agencies: Agencies such as the Confederation of Indian Alcoholic Beverage Companies (CIAA), the International Dairy Federation (IDF), the European Hygienic Engineering & Design Group (EHEDG), Pollution Control Boards, and the Prevention of Food Adulteration Act play significant roles in ensuring food safety and quality.

Food Safety Management Systems

A robust Food Safety Management System (FSMS) is essential for identifying and addressing potential safety issues. A Hazard Analysis and Critical Control Points (HACCP) plan is instrumental in pinpointing critical points within the food manufacturing process where safety issues are most likely to occur. Food processors can develop their own HACCP food safety plans by creating detailed flowcharts that map the handling and processing of ingredients. The FDA provides templates and guidelines to assist in creating these plans.

Key Components of Food Safety Management

- ISO 22000:2018: ISO 22000 standard outlines the requirements for a food safety management system and provides a framework for effectively managing food safety responsibilities.

- Hygienic Design and Risk Assessment: Proper sanitary design and thorough risk assessment are critical to maintaining a safe food processing environment.

- Traceability: Ensuring that all ingredients and products can be traced back through the supply chain is essential for effective management and recall procedures.

- Quality Assurance Management: Implementing rigorous quality assurance protocols ensures consistent product safety and quality.

Good Manufacturing Practices (GMP)

Adherence to GMP in manufacturing is vital in maintaining high standards of hygiene and safety within food processing facilities. Key aspects include:

- Building and Facilities Design: Facilities should be designed for easy cleaning, with smooth, non-porous, and crevice-free internal walls, drainable floors resistant to acid and alkali, and protection against pests.

- Sanitization: Effective sanitization procedures, such as using 90°C water with a chlorine solution at 150 PPM and a retention time of three minutes, are necessary to manage microbial loads.

- Equipment and Installation: Equipment should be installed above floor level for easy access and cleaning, with appropriate sewage systems and disinfectant mats in place. Pipes should have minimal bends and be welded where possible to facilitate cleaning.

- Water Quality: Water used in the process should meet specific quality parameters, such as having less than 50 PPM hardness, less than 30 PPM chloride, and less than 0.2 PPM chlorine.

By adhering to these principles and maintaining stringent quality control measures, the food processing industry can ensure the production of safe, high-quality food products that meet regulatory standards and protect consumer health.

The food processing industry relies on a diverse array of equipment to ensure efficiency, safety, and product quality. Technological advancements continue to improve the functionality and capabilities of food processing equipment, enhancing productivity and meeting the evolving demands of consumers.

Webinar: Food Safety and Hygienic Risk Assessment in Food Processing Industry

Get insights about the current trends in food safety and quality management in our Emerging Food Tech Webinar series.