A Definitive Guide to Yoghurt Production

Yoghurt is a product made from fermented milk with the characteristics of bifidobacteria. Many factors influence the bifidobacteria concentration in the human digestive system, Yoghurt being one of them. In this blog, we will walk through the different types of yoghurts and the processing technologies used to understand the current trend in the global yoghurt market.

History of Yoghurt Production

The term ‘Yoghurt’ is derived from the Ottoman Turkish word ‘yoğurt’ which translates to be curdled or coagulated; to thicken. Yoghurt is seen as having footprints dating back to ancient times and being an important part of the daily diet. Yoghurt’s industrialization first occurred in 1919 by Isaac Carasso in Barcelona, Spain. He started his small business in Spain and later expanded it in the United States under the name Dannon. In 1933, Radlická Mlékárna Dairy patented another type of yoghurt: Yoghurt with added fruit jam.

Benefits of Yoghurt Processing

A mix of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus bacteria is considered to serve various health benefits, not just today but from ancient times. This microflora of yoghurt improves gut health, which in turn helps in better digestion. Other than this, benefits yoghurt has:

- Its microflora provides relief from diarrhoea, as it acts as an antidote when you're on antibiotics.

- Yoghurt bacteria help boost vitamin B production in our body.

- Probiotics present in yoghurt help boost the immune system and also help to prevent the overgrowth of any fungus-related infection.

- The lactic acid present in yoghurt accelerates bowel movement, further preventing constipation or any diarrhoea-related infection. Also increases gut acidity to speed up the digestion process.

- Protects from inflammatory infections and peptic ulcers.

Different types of yoghurt provide different types of health benefits to us, with a few improving your gut health and a few preventing any severe infections.

Difference Between Yoghurt and Curd

Yoghurt and curd are both popular fermented dairy products, but they differ significantly in their origins, production processes, and bacterial cultures used. The basic difference between the both is their method of production. Preparation of yoghurt requires adding live strains of two bacteria Lactobacillus bulgaricus and Streptococcus thermophilus whereas, curd can be made at home simply by curdling the milk. Yoghurt requires the milk to be pasteurized at 90°C with a holding time of 5-10 minutes and curd is usually warmed to a lower temperature of 30-40°C.

While both yoghurt and curd are fermented milk products, they are distinct in several key ways. Yoghurt is typically made with specific bacterial cultures and a controlled fermentation process, resulting in a consistent, tangy product. Curd, on the other hand, is often made with natural or less standardized bacterial cultures and a simpler fermentation process, leading to a milder, more variable product. Both have unique places in culinary traditions around the world.

Different Types of Manufacturing Yoghurt

Yoghurt being a fermented milk product, the type of milk used to produce yoghurt characterises what type of yoghurt is being made. There are different types of yoghurt available on the market, like:

- Set

- Stirred

- Drinking

- Frozen

- Flavored

- Aseptic

- Concentrated

- Quarg or Quark

These different types of yoghurt making process require different incubation methods and temperatures depending on their viscosity.

- Set Yoghurt: It is incubated and cooled in the final package and is characterised by a firm jelly-like texture. Set yoghurt is usually a very low-solids content yoghurt also known as dahi in India.

- Stirred Yoghurt: It is incubated in a tank, and the final coagulum is broken by stirring before cooling and packing. The texture of a stirred yoghurt will be less firm than that of a set yoghurt. There is usually a slight reformation of the coagulum after the yoghurt has been packed.

- Drinking Yoghurt: It is very similar to stirred yoghurt, having the coagulum broken before cooling. In a drinking yoghurt, the agitation used to "break" the coagulum is severe. A very small amount of coagulum will reoccur, if there is any reformation, after packing. Drinking yoghurt is to be served chilled or at ambient temperature.

- Frozen Yoghurt: Frozen yoghurt requires a different recipe and usually consists of a thin yoghurt blended with a high-solids ice cream base mix. Frozen yoghurt is achieved by pumping it through a freezer in a fashion similar to ice cream. The texture of the finished product is mainly influenced by the freezer.

- Flavoured Yoghurt: Yoghurt with various flavours and aromas has become very popular in recent times. The flavour is usually added to the yoghurt at or just before filling the containers. A few common additives to this type are fruit or berries; they are usually added as a puree or as whole fruit in a syrup. The best example is Greek yoghurt.

- Aseptic Yoghurt: Aseptic yoghurt is nothing but yoghurt that is being filled into an aseptic pack. This type of yoghurt has a longer shelf life and is also free from any kind of preservative. Additionally, you can store it in ambient conditions.

- Concentrated Yoghurt: It is inoculated and fermented in the same manner as a stirred yoghurt. Following the "breaking" of the coagulum, the yoghurt is concentrated; this is often done under vacuum to reduce the temperature to the required level.

- Quarg or Quark Yoghurt: This is a higher solids yoghurt using Mesophilic cultures with lower incubation temperatures but longer incubation time or Thermophilic cultures with a higher temperature and lower incubation time.

Yoghurt production is a relatively simple process as compared to other dairy products. The main ingredient used in the preparation of yoghurt is milk, and the type of yoghurt depends on the type of milk used. For full-fat yoghurt, whole milk is used, whereas for low-fat yoghurt, low-fat milk is used, and for zero-fat or no-fat yoghurt, skimmed milk is used.

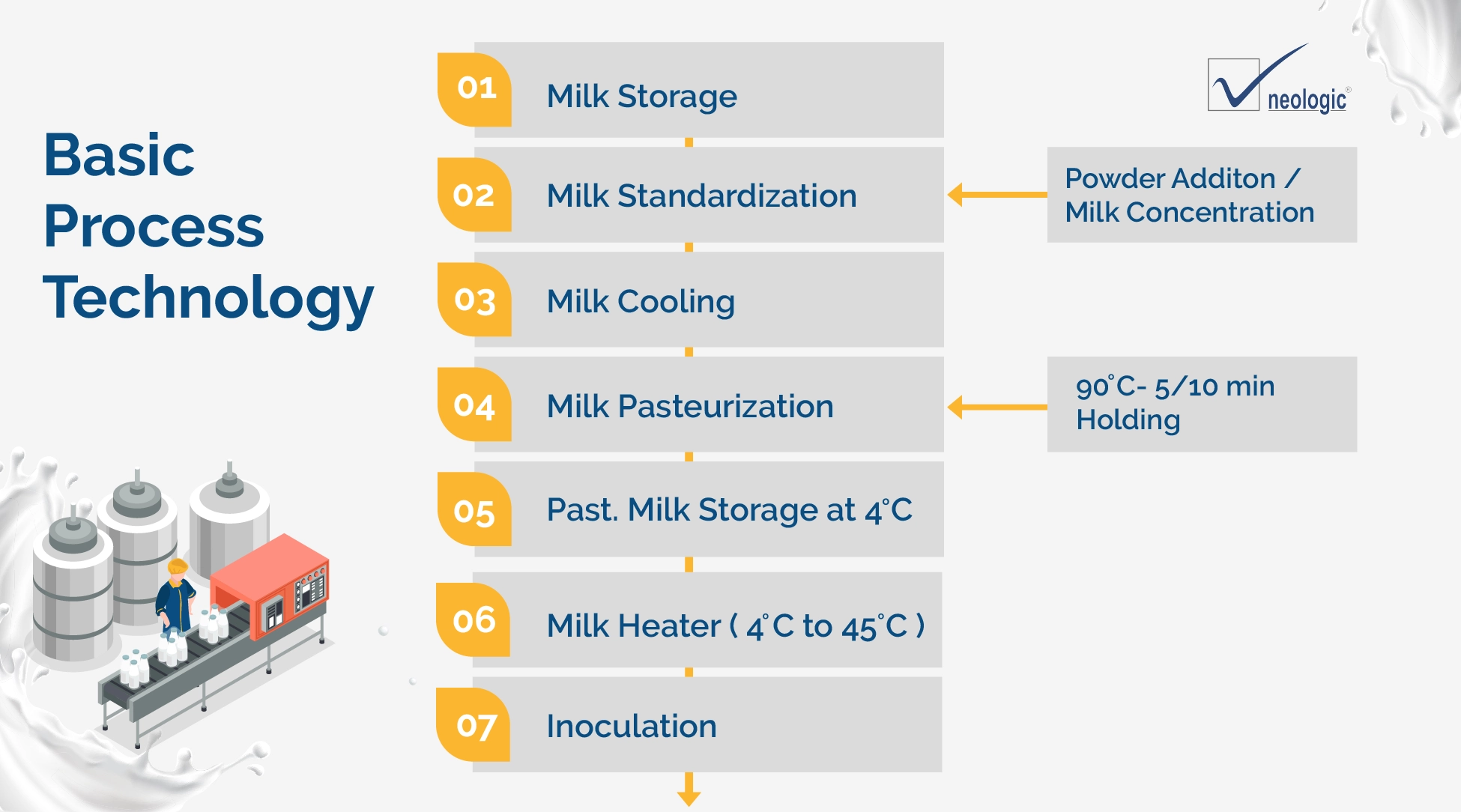

Basic Yoghurt Process Technology

The basic process to manufacture yoghurt is to add milk powder or milk concentration, pasteurisation, cooling, and inoculation with starter bacteria. This is the basic process of preparing yoghurt, also known as dahi.

The yoghurt process starts with first handling and storing the milk received from the dairy. Then the milk further proceeds for standardisation, as in yoghurt the fat percentage differs from 0.5% to 3.5%, whereas the SNF (solids not fat) values present are much higher, i.e., around 8.5% to 9%. These SNF values are different for different types of yoghurt. While standardizing the milk, milk powder or milk concentration is being added; both of these are common practices, but in India, adding dry powder to solidify is a common practice. After standardization, milk goes in for cooling and then pasteurization at 90 °C for 5 to 10 minutes. Yoghurt milk is pasteurized at a higher temperature for protein denaturalization. Along with this, homogenization and deaeration also take place to achieve a smooth texture for the yoghurt. Now, after the milk gets pasteurized, it's stored in a pasteurized milk storage tank at 4 °C. Further, as per requirement, the milk is transferred to a heating tank, and the milk gets heated from 4°C to 45°C. After heating, the milk is further sent for inoculation.

*Image representation of the process

This is the basic yoghurt processing method used. Post-inoculation, the process changes for different types of yoghurts.

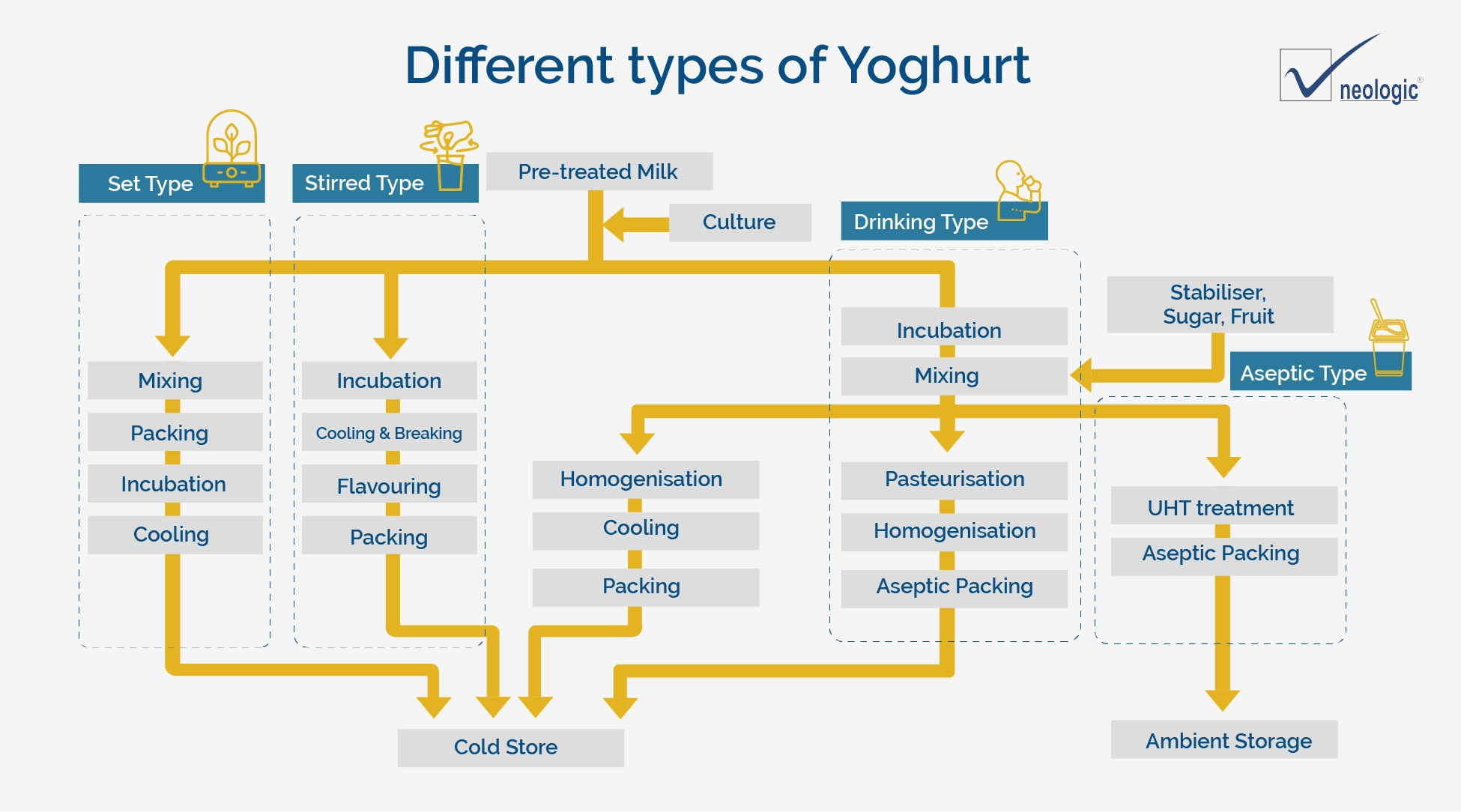

Processing Technology Used for Different Types of Yoghurt Production

Yoghurt production involves several key processing technologies that vary depending on the yoghurt that is being produced.

Types of yoghurt and their processing technologies:

- Set Yoghurt: After inoculation, the yoghurt is dispensed into containers and then incubated. The fermentation occurs in the final packaging, and the texture is firm and gel-like.

- Stirred Yoghurt: The fermentation occurs in large vats. After reaching the desired acidity, the yoghurt is stirred to achieve a smooth consistency, then cooled and packaged, and the texture is creamy and smooth. Stirred yoghurt requires rapid cooling, mostly within 30 minutes.

- Drinkable Yoghurt: After fermentation, the yoghurt is stirred to a low viscous consistency to be drinkable, and then it is homogenized and packaged.

- Frozen Yoghurt: Similar to stirred yoghurt but with the addition of sweeteners and stabilizers. The mixture is then frozen, and its texture is soft and creamy, similar to ice cream.

Each type of yoghurt requires specific adjustments and technologies to achieve its unique texture, flavour, and consistency. The choice of technology depends on the desired final product and production scale.

*Image representation of the process

Neologic Engineers provides equipment that adds dry powder to milk without adding unnecessary air. We also supply a sophisticated system for milk concentration by way of RO.

Quality Control and Challenges in Handling Viscous Yoghurt

In the yoghurt market, quality and texture are of utmost importance and product viscosity is its correlated parameter. Yoghurt is usually consumed in a semi-solid state but with changing trends, consumers demand less viscous yoghurt. Adding texture to the yoghurt is an intricate task as it affects the viscosity of the yoghurt. Producers of processed yoghurt need to ensure that their yoghurt processing lines are of high quality enabling continuous monitoring of yoghurt’s texture and viscosity.

Yoghurt manufacturers often face challenges with the ever-changing nature of yoghurt consumption. Consistency in yoghurt production is the first challenge. Every producer wants the same level of quality in their product. To ensure consistent end product qualities, within and between batches, it is imperative to handle all of the yoghurt in a line in the same manner.

A few producers even face the challenge of plant inflexibility. Now yoghurt processing lines require the capability to produce different kinds of yoghurts, ranging from high viscous to low viscous along with different fat levels and lactose-free variants.

There are quality assurance parameters of the yoghurt set that check the characteristics of yoghurt including appearance, texture and taste. Certain factors affect these characteristics resulting in low-quality produce.

Factors affecting the quality of yoghurt

Any deviation from the set quality assurance parameters causes a defect in the final product. Various factors that affect the quality of yoghurt are:

- The quality of milk used for manufacturing yoghurt.

- The received milk requires proper treatment and storage as exposing milk to an open environment might contaminate the milk and also multiply the bacterial growth in the milk. So, it is important to have proper standardization, deaeration, homogenization, and heat treatment.

- Adding too much starter culture also hampers the quality of yoghurt as it increases the acidic nature of the yoghurt. The quality of culture also plays an important part in the yoghurt processing.

- Yoghurt producers need to have a plant design that is flexible enough to handle various yoghurt varieties. The equipment used should gently treat the yoghurt to achieve the set texture and viscosity of the yoghurt.

Growth Potential of The India Yoghurt Market

With its natural high-protein content, microbial properties, and low-fat content, Yoghurt has gained substantial popularity among health-conscious consumers. With a consistent growth rate, the India Yoghurt Market is expected to grow annually by 8.97% (CAGR 2024-2029).

Increasing population, rising incomes, and improving standards of living are resulting in the expected average consumption per person going up to 12.4 kg in 2024. The revenue of the India Yoghurt Market in 2024 is expected to be US$32.83bn. In the case of the Retail Yoghurt market, players like GCMMF, Mother Dairy, Nestle India and Parag Milk Foods have held more than 50% of the market.

With the rapidly rising demand for yoghurt, several brands have introduced flavoured yoghurt, low-fat and no-fat yoghurt, and frozen yoghurt – a healthy alternative to ice creams. This healthy and tasty gut-friendly option is undergoing many innovations in 2024, like:

- Enhanced nutritional appeal: With the growing interest in gut health, the demand for health-promoting products has increased. Yoghurt with its active bacterial culture is considered good for improving digestion and this has led dairy producers to focus more on probiotic aspects of yoghurt. It is also seen that a few producers are also focusing on adding extra vitamins to the yoghurt to enhance its nutritional value. Yoghurt production is just not limited to adding extra vitamins but also reducing the sugar content in it making it a preferable option.

- Plant-based Yoghurt: As people are shifting their dietary habits to healthier options and vegan choices, plant-based yoghurt is their first preference. Plant-based yoghurts are made from different milks of soy, almond, rice, coconut, etc., it’s also beneficial for those who are lactose intolerant.

- Clean Label: As people become health-conscious, they demand to know what’s added to their food and in what proportion. It’s observed that people now demand ‘Clean Label’ products, especially yoghurt i.e., yoghurt with less additives. The one who designs their yoghurt processing lines that treat the product as gently as possible have a higher potential to grow in this market.

In conclusion, yoghurt, with its rich history and diverse manufacturing processes, has established itself as a vital component of diets worldwide. From set to stirred, and from frozen to plant-based varieties, each type offers unique health benefits, primarily due to its probiotic content. The evolution of yoghurt processing technologies has enhanced its quality, consistency, and nutritional value, catering to changing consumer preferences. In markets like India, the demand for yoghurt is growing rapidly, driven by health-conscious consumers and innovative product offerings. As yoghurt continues to evolve, it remains a nutritious and versatile option in the global dairy industry.

Table of Content

- History of Yoghurt

- Benefits of Yoghurt

- Difference Between Yoghurt and Curd

- Different types of Yoghurts

- Basic Yoghurt Process Technology

- Processing technology used for different types of Yoghurts

- Quality Control and Challenges in Handling Viscous Yoghurt

- Factors affecting the quality of yoghurt

- Growth Potential of the Yoghurt Market

Webinar: New Trends and Technologies in Yoghurt Processing

Get insights about the ever-evolving yoghurt market trends and technological advancements in our Emerging Food Tech Webinar series.