What is Milk Standardization?

Cream and milk are fat-in-water or oil-in-water emulsions. Whereas, whole milk is an emulsion of fat globules in milk serum. The purpose of milk standardization is to regulate the fat content of the milk by either complete or partial removal of fat or the addition of fat or other ingredients.

It's a process that brings precision in every pour of milk. The considered compositional parameters are fat and SNF for market milk, although most of the time, only fat may be taken into account for standardization. For specific products, even protein content may be standardized.

If the needed constant fat content is higher than the incoming milk, a determined portion of the skim milk will be removed, resulting in a skim milk surplus that cannot be used unless the dairy has a Milk Powder plant to convert the excess skim milk into SMP. Typically, standardization takes place at a lower fat level than the incoming whole milk. As a result of the procedure, there is a surplus of fat that can be used to manufacture extra fat-required products, such as butter.

In standardization, it is important to be able to measure, record and control processing parameters precisely. Regular attention should be paid to the accuracy of the readings, as the measurement is a critical control point for milk processing.

Need for Milk Standardization

Fat standardization is a particularly successful strategy in milk processing because it ensures uniform product quality and allows surplus fat to be used for more fat-needing products.

It is required in milk processing for the following reasons:

- To meet the legal criteria for specific milk/dairy products.

- To deliver a consistent product to the consumer.

- To ensure production economics by managing fat in milk; and

- To decrease fat losses in milk.

Methods of Standardization

The process of standardizing milk started with the separator itself. A separator divides the whole milk into two main components, cream and skim milk. To get standardized milk with a lower fat content than whole milk, a remixing of cream into skim milk is required. It is then possible to get a large variety of milk fat contents without having to vary anything within the separator. One way of doing this is by manually mixing in separate tanks, but it is more effective when done inline in pipes.

Standardization can be accomplished in three ways: batch, continuous, and automatic. They all involve separating milk into skim milk and cream and then blending only the amounts specified.

Batch Standardization

It is a method that is most typically employed in small and medium-sized dairies. The fat content of whole milk is measured and stored in a silo. A portion of the milk is removed and divided into skim milk and cream. The amount of skim milk or cream needed is calculated (Pearson square method) or determined from standard charts and then added to the bulk milk while it is continuously agitated. The bulk milk is retested to ensure that the fat content meets the specified level. If it is not, additional changes are done until the batch is properly standardized. The time required for agitation, testing, and final mixing is a disadvantage of batch standardization.

Furthermore, it is a labour-intensive approach that necessitates the use of extra tanks for mixture and storage.

Continuous Standardization

Continuous standardization involves the use of an inline milk fat sampler in conjunction with a testing apparatus that samples, measures, and displays the fat level at equal time intervals. The operator looks at the displayed fat content and adjusts the parameters to blend the cream into the skim milk line. This is accomplished by manually adjusting valve displacement prior to the sample point to achieve the desired fat content.

Automatic Standardization

It is a recent addition to the ongoing process. A microprocessor unit attached to the sensor (tester) system replaces the operator. The microprocessor unit knows the desired fat content and flow rates of the skim milk and cream. It receives sensor system signals and responds by altering the control valve, which controls the amount of cream added to the skim milk.

This computerized technique saves time and labour while ensuring more precise uniformity than other methods. Accurate measurement, precise fat content sensing, efficient separation, and determining the appropriate amount of skim milk or cream to blend are all required for standardization.

Limitations in Current Milk Fat Standardization

- Due to tight regulations, keeping the fat percentage within a narrow tolerance is crucial.

- Excess fat in milk may result in a loss because it could have been used for other fat-requiring goods.

- A low-fat percentage carries severe penalties imposed by governing organizations.

- The product's consistency is maintained by keeping fat contents under a certain tolerance.

- The batch and continuous standardization methods are unreliable, and the fat content of milk changes across batches.

- Currently, standardization is accomplished through the operator's judgment, which is prone to inaccuracy.

- In batch standardization, the sole choice is to mix the milk and cream in the proper proportions in a separate tank, which needs additional storage, processing, and time.

- Auto standardization is a recent method that is appealing for industrial demands.

- The fat content is adjusted to the desired level during auto standardization by remixing a specified proportion of the cream flow from the separator to the skim milk line.

- To obtain standardized milk with the required fat content, the specified amount of cream is blended with skim milk in an in-line system immediately after the separator.

- Closed-loop feedback control is required to adjust fat contents depending on all interdependent variable parameters.

Basic Steps in AutoFat Standardization

- Separating the incoming milk is the first step in the standardization procedure.

- Milk is classified into two types based on its fat content: cream milk and skim milk.

- To make a standardized milk portion, the calculated cream is added back into the skim milk.

- The leftover cream is used to make butter, paneer, and ghee, among other cream-based products.

Automation System for Milk Standardization

The separator in an in-line fat standardization procedure for a dairy product has a dairy product inlet and an output for cream and skim milk. The fat content of cream exceeds that of skim milk. Detecting the fat content of cream and skim milk, as well as regulating the fat content of departing milk using a control device attached to the cream line, is part of the technique.

The sections that follow present the numerous concerns and aspects that must be taken into account when building the automation and instrumentation for automatic in-line fat standardization.

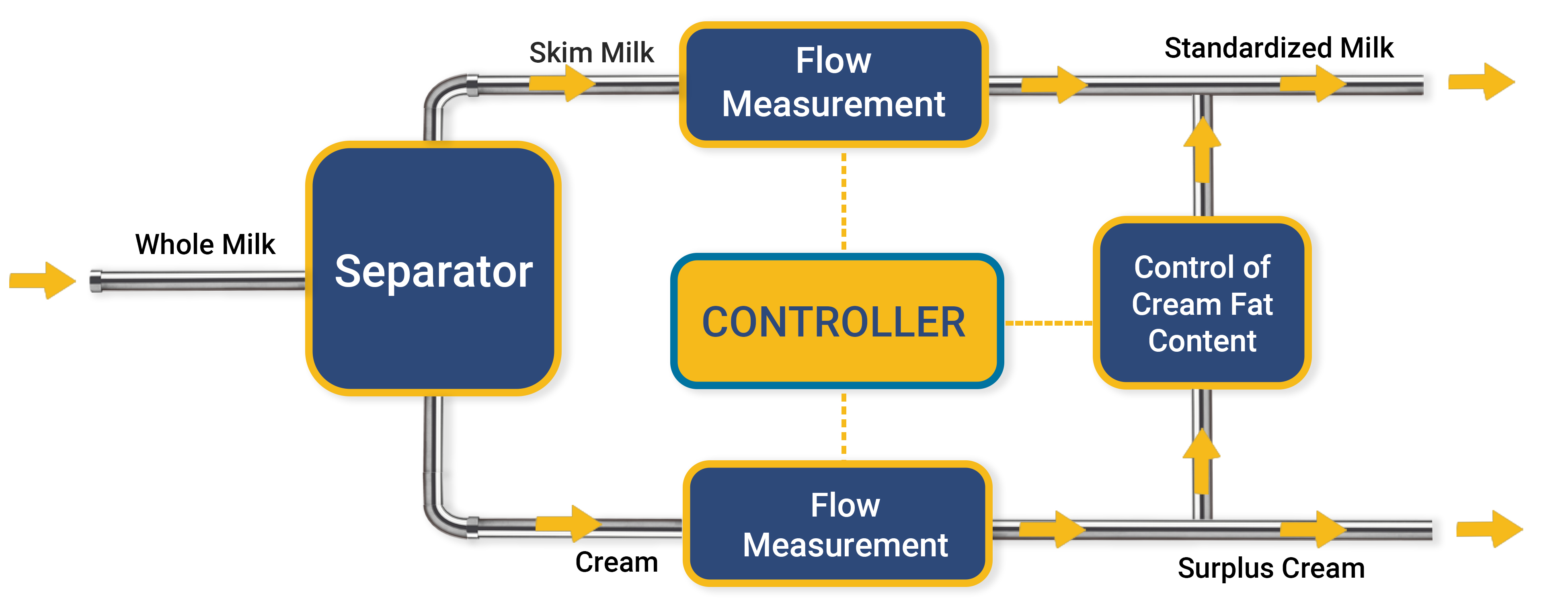

This graphic depicts a closed-loop feedback control system used in a continuous automatic milk fat standardization system. An automated controller will operate the system. Sensors installed on milk and cream lines will detect density (fat) measurements and send a signal to the control valve, causing the flow of cream to change. It will include mathematical modelling of incorrect signals as well as determining system constants to drive the control valve.

The automation system and the field instrumentation system comprise the control system. The control system is the brain that regulates the mixing ratio of the skimmed milk and cream streams. The algorithm specifications will detail the type of field instruments and actuators required to achieve accurate fat% control in standardized milk.

Standardization Calculation

The actual controller calculation employed a mass balance algebraic approach as ALU (Arithmetic & Logic Unit) in Fat Controller is compatible, makes calculations simple, and can generate real-time float points. The calculations are outlined further down.

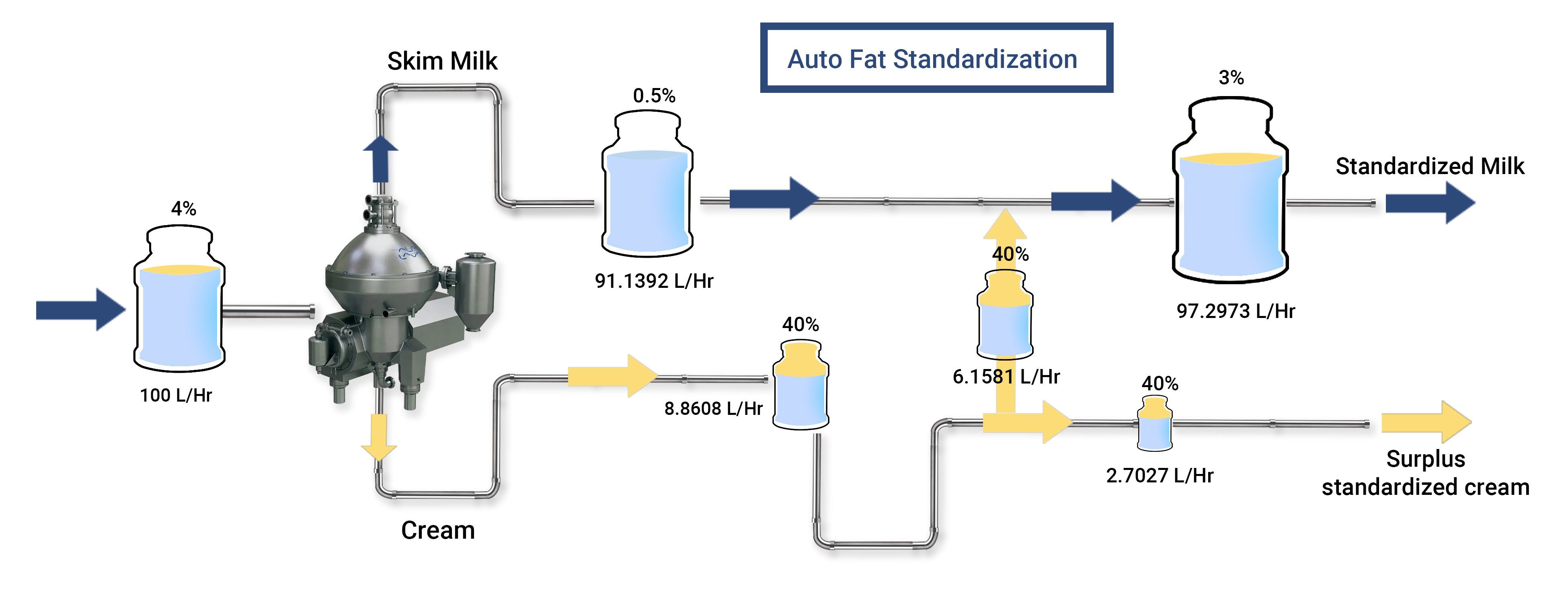

Assume the system is supplied at a constant flow rate of 100 lit/hr of milk with a fat content of 4%. The separator skimming is stable, and the system thinks itself to be at an ideal state. The performance of the separator determines the fat content and flow rate of each stream. The separator normally delivered. a fat content of 40% for the cream stream and 0.5% for the skim milk stream. The fat percentage of standardized milk must be 3%.

The following representation used in the calculation,

Abbreviation Table

| Terms | Fat (%) | Flow (Lit/Hr) |

|---|---|---|

| Incoming Milk | Fi | Vi |

| Cream | Fc | Vc |

| Skim Milk | Fs | Vs |

| Standardize Milk | Fo | Vo |

| Surplus Cream | Fx | Vx |

| Cream Remix | Fm | Vm |

As provided,

- Incoming milk flow = Vi = 100 lit/hr

- Incoming milk fat = Fi = 4 %

- Cream Fat = Fc = 40 %

- Skim milk fat = Fs = 0.5 %

- Standardize milk fat = Fo = 3 %

1. Skim milk stream flow rate:

The mass balance algebraic equation for skim milk

- Vs = Vi × ((Fc-Fi)) / ((Fc-Fs))

- Vs = 100 × ((40-4)) / ((40-0.5))

- Vs = 91.1392 lit/hr

2. Cream stream flow rate:

An incoming flow is divided into two streams from the separator

- Vi = Vc + Vs

- Vc = Vi - Vs

- Vc = 100 - 91.1392

- Vc = 8.8608 lit/hr

3. Standardize milk stream flow rate:

- Vo = Vs × ((Fc-Fs)) / ((Fc-Fo))

- Vo = 91.1392 × ((40-0.5)) / ((40-3))

- Vo = 97.2973 lit/hr

4. Surplus cream stream flow rate:

- Vx = Vi - Vo

- Vx = 100-97.2973

- Vx = 2.7027 lit/hr

5. Cream requires to remix:

- Vm = Vc - Vx

- Vm = 8.8608 - 2.7027

- Vm = 6.1581 lit/hr

This image shows the calculated flow and fat at multiple locations. These calculated values are utilized to regulate the flow of the control valve and ensure the system is working without any errors by cross-checking values at each stage with feedback provided by instruments and actuators.

Parameters Affecting Milk Fat

Milk fat composition did not remain the same throughout because many factors can influence milk composition. This is an important point to remember when evaluating the potential to improve milk composition and component yields.

The physical properties of milk and milk products are of great importance to dairy technology, as they will affect most of the unit operations used during their processing. Rheological properties are also studied for assessing and monitoring the quality of milk products.

Physical properties impact on milk composition are:

- Milk appearance

- Density

- Viscosity

- Pressure

- Temperature

- Flow

- Freezing point

- Melting point

- Acidity

- pH value

- Fat hardness

- Fat crystallization

When milk leaves the udder at 37℃, the fat globules quickly alter shape when subjected to modest mechanical treatment such as pumping and running in pipes. Fatty acids account for approximately 90% of milk fat. The hardness of the fat is affected by temperature changes. Hard fat has a higher concentration of high melting fatty acids. Soft fat has a larger concentration of low melting fatty acids. Fat globules are extremely sensitive and easily broken during the crystallization process, which can be opened up by even mild mechanical manipulation. Fat crystallization produces fusion heat, which raises the temperature. (40% cream cooled from 60℃ to 7-8℃ becomes 3-4℃ warmer during crystallization).

Milk composition and component yields can be influenced by genetics and environment, as well as milk production level, lactation stage, disease (mastitis), season, and cow age. Milk fat and protein concentrations are highest in early and late lactation and lowest during peak milk production through mid-lactation. Certainly, genetics plays a role, but the alterations are undetectable.

Milk standardization is a crucial process that ensures the consistency and quality of milk-based products. From ensuring regulatory compliance to maximizing product utilization, standardization plays a vital role in the dairy industry.

Consumers may not always think about the intricate processes involved in producing the milk they enjoy every day, but the importance of milk standardization cannot be overstated. So, the next time you enjoy a glass of milk or a slice of buttered toast, take a moment to appreciate the care and precision that went into standardizing the milk that made it all possible.

Prepared By,

Suraj Bhosale