Beverage Plant Machine Manufacturers

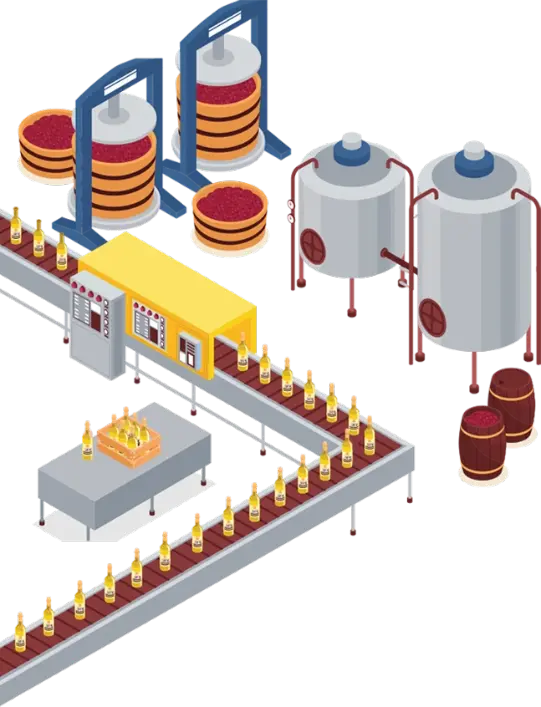

We design and supply unique processing solutions for beverage manufacturing. We manufacture various plant equipment like modular systems and lines for complete beverage processing plants on a turnkey basis.

Neologic Engineers hold decades of experience in the beverage processing industry. We provide state-of-the-art processing plants of high quality that are energy and cost-efficient. Our highly experienced team is adept at providing automated solutions for:

- Ready to Serve (RTS) & Ready to Drink (RTD) Processing Lines

- Carbonated Soft Drink (CSD) Processing Lines

- Carbonated Fruit Drink (CFD) Processing Lines

- Energy Drink & Tonic Water Processing Lines

In soft drink production, beverage processing equipment is useful for monitoring and measuring the concentration and addition of flavourings and other additives.

Beverage processing equipment uses automated solutions for bottling, labelling, and packaging. Our automated line solutions include conveyor belts, flow meters, pressure transmitters, and gauges.

We set up your beverage processing plant with our state-of-the-art equipment with timely execution of projects. Our beverage processing lines consist:

- Sugar Syrup Preparation

- Pulp Unloading and Transfer

- Pectin and other Ingredient Mixing

- Precoat System

- Blending and Homogenization System

- Pasteurization/Sterilization/Aseptic Sterilization

- Sugar Syrup Preparation

- Concentrate Preparation

- Precoat System

- Blending Section

- Co2 Carbonation

- Sugar Syrup Preparation

- Concentrate Preparation

- Precoat System

- Pectin System (optional)

- Blending Section

- Pasteurization Section

- Co2 Carbonation

- Sugar Syrup Preparation

- Pectin and other Ingredient Mixing

- Precoat System

- Concentrate Preparation

- Blending and Homogenization System

- Pasteurization Section

Achieve the desired productivity and quality goals with our highly efficient processing equipment. Our equipment provides cutting-edge technology for accurate and precise sensors and user-friendly data solutions.

We leverage our diverse portfolio of quality weighing equipment, measurement solutions, formulation/batching software, product inspection systems, and services to enhance your compliance, quality, and productivity.

We also provide the engineering and design for utility distribution for utilities like refrigeration (ice water/glycol/brine), electricity from MCC onwards, LP steam line with the condensate return, soft-process water, RO water, compressed – instrument(Industrial) grade air as required for the smooth and efficient operation of the Beverage line as per the rated capacity.

As beverage pasteurizer manufacturers, we use product-inspection technology to ensure safe, standard products and packaging.

As a leading Beverage plant manufacturer, Neologic Engineers understands how important high precision control and monitoring equipment is to the beverage processing Industry. Our highly experienced team is adept at providing automated solutions for the beverage industry.

Through design expertise, we respond quickly to evolving consumer demands and safety compliance standards and improve productivity while reducing production costs and maintaining product quality.

In the beverage industry, the end product must be safe to consume, in all aspects. Neologic Engineers is a trusted beverage machinery manufacturer known to provide:

- The design, supply, erection, and commissioning of beverage processing plant equipment and their utilities for turnkey projects and Greenfield projects.

- Complete care of beverage processing automation.

- Undertake project engineering consultancy, project process design, process economy and feasibility, utilities design and supply.

- Revamp and modernize the existing beverage processing plant to a suitable automation level.

Our precise solutions will help you:

- Obtain 100% transparency in materials transfer and inventory control.

- Set up state-of-the-art automated dosing and batching systems.

- Ensure accurate materials flow for hassle-free order fulfilment.

- Efficient material handling.

- Modular design and easy integration with existing system.

- PLC-based fully automated CIP station.

- Optimized lye, acid, and water steam consumption.

Neologic Engineers Think Tank comprises individuals specialized in the Beverage industry. With their years of experience and expertise, you get the upper hand when setting up a beverage processing plant.

Our Clientele

Get in touch with our experts for your dairy equipment needs.

Our highly qualified team will help you right from concept to commissioning.